PLE

Overview

Technical Data

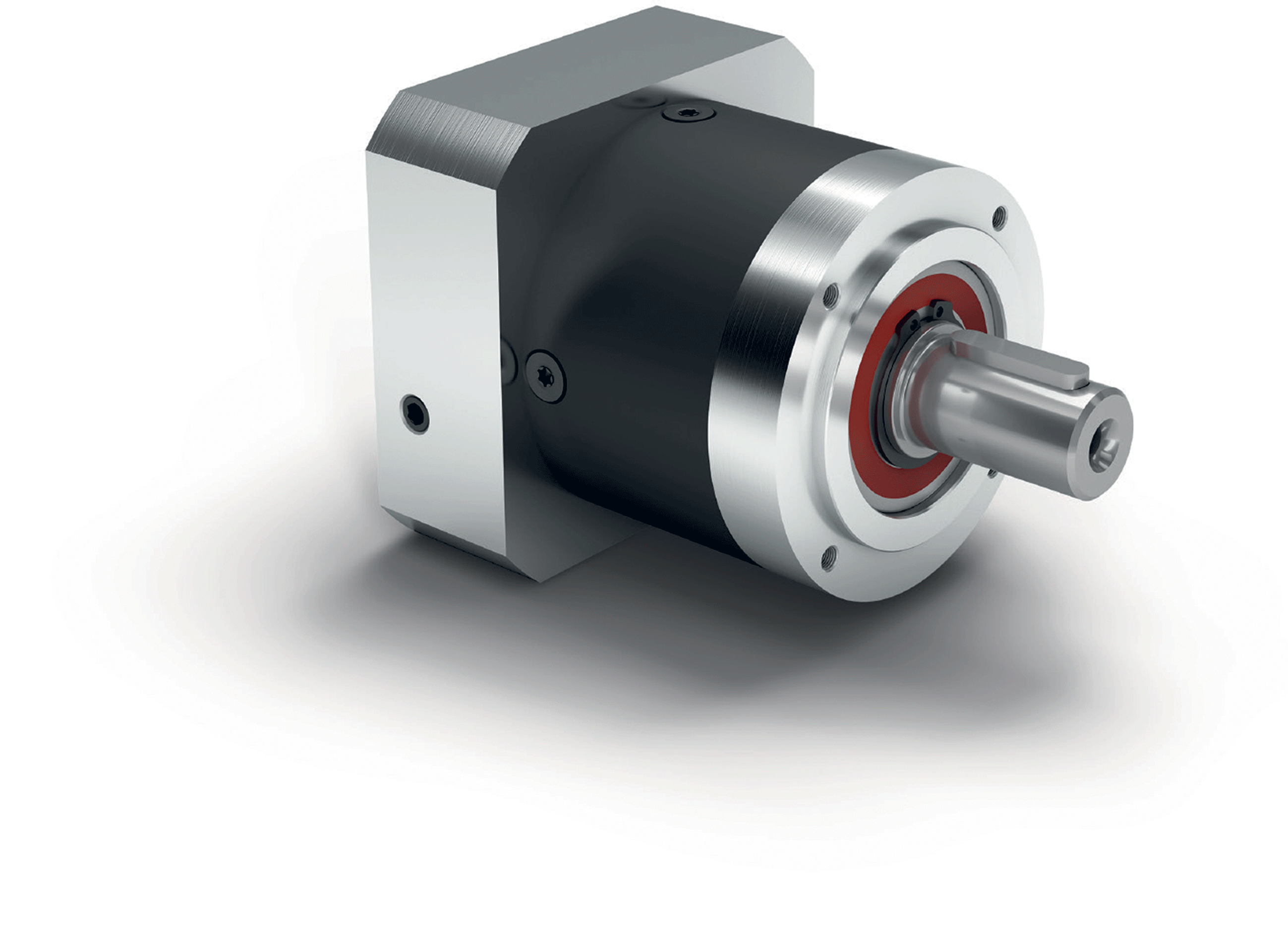

Description

PLE® is a planetary gearbox perfectly compatible with the brushless motors of the SR and B series.

It is a very light product but in any case extremely performing, ideal even for heavy production cycles thanks to the design with reduced friction bearing and optimized lubrication.

A high level product at a fair and affordable price.

Developed and produced in Germany by Neugart® for HDT.

Torque Data.

| Nominal output Torque | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | Ratio | Stage | ||

| 11 | 28 | 85 | 115 | 400 | 3 | 1 | |||

| 15 | 38 | 115 | 155 | 450 | 4 | 1 | |||

| Nominal output torque | T2N | Nm | 14 | 40 | 110 | 195 | 450 | 5 | 1 |

| 8,5 | 25 | 65 | 135 | - | 7 | 1 | |||

| 6 | 18 | 50 | 120 | 450 | 8 | 1 | |||

| 5 | 15 | 38 | 95 | - | 10 | 1 | |||

| 16,5 | 44 | 130 | 210 | - | 9 | 2 | |||

| 20 | 44 | 120 | 260 | 800 | 12 | 2 | |||

| 18 | 44 | 110 | 230 | 700 | 15 | 2 | |||

| 20 | 44 | 120 | 260 | 800 | 16 | 2 | |||

| Nominal output torque | T2N | Nm | 20 | 44 | 120 | 260 | 800 | 20 | 2 |

| 18 | 40 | 110 | 230 | 700 | 25 | 2 | |||

| 20 | 44 | 120 | 260 | 800 | 32 | 2 | |||

| 18 | 40 | 110 | 230 | 700 | 40 | 2 | |||

| 7,5 | 18 | 50 | 120 | 450 | 64 | 2 | |||

| 20 | 44 | 110 | 260 | - | 60 | 3 | |||

| 20 | 44 | 120 | 260- | - | 80 | 3 | |||

| 20 | 44 | 120 | 260 | - | 100 | 3 | |||

| 18 | 44 | 110 | 230 | - | 120 | 3 | |||

| Nominal output torque | T2N | Nm | 20 | 44 | 120 | 260 | - | 160 | 3 |

| 18 | 40 | 110 | 230 | - | 200 | 3 | |||

| 20 | 44 | 120 | 260 | - | 256 | 3 | |||

| 18 | 40 | 110 | 230 | - | 320 | 3 | |||

| 7,5 | 18 | 50 | 120 | - | 512 | 3 |

| Max. output torque | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | Ratio | Stage | ||

| 17.5 | 45 | 136 | 184 | 640 | 3 | 1 | |||

| 24 | 61 | 184 | 248 | 720 | 4 | 1 | |||

| Max.output torque | T2max | Nm | 22 | 64 | 176 | 312 | 720 | 5 | 1 |

| 13.5 | 40 | 104 | 216 | - | 7 | 1 | |||

| 10 | 29 | 80 | 192 | 720 | 8 | 1 | |||

| 8 | 24 | 61 | 152 | - | 10 | 1 | |||

| 26 | 70 | 208 | 336 | - | 9 | 2 | |||

| 32 | 70 | 192 | 416 | 1280 | 12 | 2 | |||

| 29 | 70 | 176 | 368 | 1120 | 15 | 2 | |||

| 32 | 70 | 192 | 416 | 1280 | 16 | 2 | |||

| Max. output torque |

T2max | Nm | 32 | 70 | 192 | 416 | 1280 | 20 | 2 |

| 29 | 64 | 176 | 368 | 1120 | 25 | 2 | |||

| 32 | 70 | 192 | 416 | 1280 | 32 | 2 | |||

| 29 | 64 | 176 | 368 | 1120 | 40 | 2 | |||

| 12 | 29 | 80 | 192 | 720 | 64 | 2 | |||

| 32 | 70 | 176 | 416 | - | 60 | 3 | |||

| 32 | 70 | 192 | 416 | - | 80 | 3 | |||

| 32 | 70 | 192 | 416 | - | 100 | 3 | |||

| 29 | 70 | 176 | 368 | - | 120 | 3 | |||

| Max. output torque |

T2max | Nm | 32 | 70 | 192 | 416 | - | 160 | 3 |

| 29 | 64 | 176 | 368 | - | 200 | 3 | |||

| 32 | 70 | 192 | 416 | - | 256 | 3 | |||

| 29 | 64 | 176 | 368 | - | 320 | 3 | |||

| 12 | 29 | 80 | 192 | - | 512 | 3 |

| Emergency stop torque | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | Ratio | Stage | ||

| 22.5 | 66 | 180 | 390 | 800 | 3 | 1 | |||

| 30 | 88 | 240 | 520 | 900 | 4 | 1 | |||

| Emergency stop torque | T2stop | Nm | 36 | 80 | 220 | 500 | 900 | 5 | 1 |

| 26 | 80 | 178 | 340 | - | 7 | 1 | |||

| 27 | 80 | 190 | 380 | 900 | 8 | 1 | |||

| 27 | 80 | 200 | 480 | - | 10 | 1 | |||

| 33 | 88 | 260 | 500 | - | 9 | 2 | |||

| 40 | 88 | 240 | 520 | 1600 | 12 | 2 | |||

| 36 | 88 | 220 | 500 | 1400 | 15 | 2 | |||

| 40 | 88 | 240 | 520 | 1600 | 16 | 2 | |||

| Emergency stop torque |

T2stop | Nm | 40 | 88 | 240 | 520 | 1600 | 20 | 2 |

| 36 | 80 | 220 | 500 | 1400 | 25 | 2 | |||

| 40 | 88 | 240 | 520 | 1600 | 32 | 2 | |||

| 36 | 80 | 220 | 500 | 1400 | 40 | 2 | |||

| 27 | 80 | 190 | 380 | 900 | 64 | 2 | |||

| 40 | 88 | 220 | 520 | - | 60 | 3 | |||

| 40 | 88 | 240 | 520 | - | 80 | 3 | |||

| 40 | 88 | 240 | 520 | - | 100 | 3 | |||

| 36 | 88 | 220 | 500 | - | 120 | 3 | |||

| Emergency stop torque |

T2stop | Nm | 40 | 88 | 240 | 520 | - | 160 | 3 |

| 36 | 80 | 220 | 500 | - | 200 | 3 | |||

| 40 | 88 | 240 | 520 | - | 256 | 3 | |||

| 36 | 80 | 220 | 500 | - | 320 | 3 | |||

| 27 | 80 | 190 | 380 | - | 512 | 3 |

| Input speed | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | Ratio | Stage | ||

| 5000 | 4500 | 4000 | 3400 | 1350 | 3 | 1 | |||

| 5000 | 4500 | 3900 | 3500 | 1450 | 4 | 1 | |||

| Average thermal input speed at T2 and S1 | n1n | min-1 | 5000 | 4500 | 4000 | 3500 | 1700 | 5 | 1 |

| 5000 | 4500 | 4000 | 3500 | - | 7 | 1 | |||

| 5000 | 4500 | 4000 | 3500 | 2200 | 8 | 1 | |||

| 5000 | 4500 | 4000 | 3500 | - | 10 | 1 | |||

| 5000 | 4500 | 4000 | 3500 | - | 9 | 2 | |||

| 5000 | 4500 | 4000 | 3500 | 1600 | 12 | 2 | |||

| 5000 | 4500 | 4000 | 3500 | 1900 | 15 | 2 | |||

| 5000 | 4500 | 4000 | 3500 | 1800 | 16 | 2 | |||

| Average thermal input speed at T2 and S1. |

n1n | min-1 | 5000 | 4500 | 4000 | 3500 | 2100 | 20 | 2 |

| 5000 | 4500 | 4000 | 3500 | 2400 | 25 | 2 | |||

| 5000 | 4500 | 4000 | 3500 | 2700 | 32 | 2 | |||

| 5000 | 4500 | 4000 | 3500 | 3000 | 40 | 2 | |||

| 5000 | 4500 | 4000 | 3500 | 3000 | 64 | 2 | |||

| 5000 | 4500 | 4000 | 3500 | - | 60 | 3 | |||

| 5000 | 4500 | 4000 | 3500 | - | 80 | 3 | |||

| 5000 | 4500 | 4000 | 3500 | - | 100 | 3 | |||

| 5000 | 4500 | 4000 | 3500 | - | 120 | 3 | |||

| Average thermal input speed at T2 and S1. |

n1n | min-1 | 5000 | 4500 | 4000 | 3500 | - | 160 | 3 |

| 5000 | 4500 | 4000 | 3500 | - | 200 | 3 | |||

| 5000 | 4500 | 4000 | 3500 | - | 256 | 3 | |||

| 5000 | 4500 | 4000 | 3500 | - | 320 | 3 | |||

| 5000 | 4500 | 4000 | 3500 | - | 512 | 3 | |||

| Max. mechanical input speed. | n1Limit | min-1 | 18000 | 13000 | 7000 | 6500 | 6500 |

Main Features.

| Gearbox characteristics | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | STADI | ||

| Service life | tL | h | 30.000 |

|||||

| 98 | 1 | |||||||

| Efficiency at full load | ƞ | % | 97 | 2 | ||||

| 92 | 3 | |||||||

| Min. operating temperature | Tmin | °C |

-25 | |||||

| Max. operating temperature | Tmax | °C | 90 | |||||

| Protection class | IP54 | |||||||

| Standard lubrication | Grease | |||||||

| Installation position | Any | |||||||

| <15 | <10 | <7 | <7 | <6 | 1 | |||

| Standard backlash | Jt | arcmin | <19 | <12 | <9 | <9 | <10 | 2 |

| <22 | <15 | <11 | <11 | - | 3 | |||

|

|

0,7 - 1,0 | 1,7 - 2,3 | 4,3 - 5,8 | 10,8 - 14,5 | 31,0 - 37,5 | 1 | ||

| Rigidità Torsional | cg | Nm/arcmin | 0,8 - 1,0 | 1,9 - 2,3 | 4,7 - 5,8 | 11,7 - 14,5 | 30,5 - 37,5 | 2 |

| 0,8 - 1,0 | 1,8 - 2,3 | 4,5 - 5,8 | 11,2 - 14,5 | - | 3 | |||

| 0,35 | 0,9 | 2,1 | 6 | 18 | 1 | |||

| Gearbox weight | mG | kg | 0,45 | 1,1 | 2,6 | 8 | 22 | 2 |

| 0,55 | 1,3 | 3,1 | 10 | - | 3 | |||

| Standard surface | Housing: Steel - nitrocarburized and post-oxdized( black ) | |||||||

| Rumorositಠ| Qg | dB(A) | 58 | 58 | 60 | 65 | 70 | |

| Max.beding moment based in the gearbox input flange | Mb | Nm | 3 | 8 | 16 | 40 | 140 | |

| Motor flange precision | DIN 42955-N | |||||||

| Note: (2) Livello di rumorosità a 1 m di distanza; misurato ad un nr. di giro pari a n1= 3000 min-1 senza carico; rapporto i=5 |

||||||||

Load shaft.

| Output shaft loads | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | |||

| Radial force for 20.0000 h (6)(7) | Fr20.000h |

N | 200 | 400 | 750 | 1750 | 5000 | |

| Axial force for 20.000 h(6)(7) | Fa20.000h | N | 200 | 500 | 1000 | 2500 | 7000 | |

| Radial force for 30.000 h(6)(7) | Fr30.000h | N | 160 | 340 | 650 | 1500 | 4200 | |

|

Axial force for 30.000 h(6)(7) |

Fa30.000h | N | 160 | 450 | 900 | 2100 | 6000 | |

| Static radial force(7)(8) | Fr r Stat | N | 200 | 700 | 1250 | 2000 | 5000 | |

| Static axial force(7)(8) | Fa Stat | N | 240 | 800 | 1600 | 3800 | 11000 | |

| Tilting moment for 20.000 h(6)(8) | Mk20.000h | Nm | 5 | 14 | 31 | 101 | 474 | |

| Tilting moment for 30.000 h(6)(8) | Mk30.000h | Nm | 4 | 12 | 27 | 86 | 398 | |

|

Note: |

||||||||

Inertia.

| Moment of inertia | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | STADI | ||

| 0.014 - 0.027 | 0.065 - 0.128 | 0.359 - 0.654 | 1.378 - 2.361 | 3.726 - 11.999 | 1 | |||

| Mass moment of inertia | J | Kgcm2 | 0.015 - 0.026 | 0.066 - 0.121 | 0.365 - 0.613 | 1.414 - 2.288 | 3.502 - 10.087 | 2 |

| 0.015 - 0.025 | 0.066 - 0.076 | 0.365 - 0.590 | 1.413 - 2.196 | - | 3 |

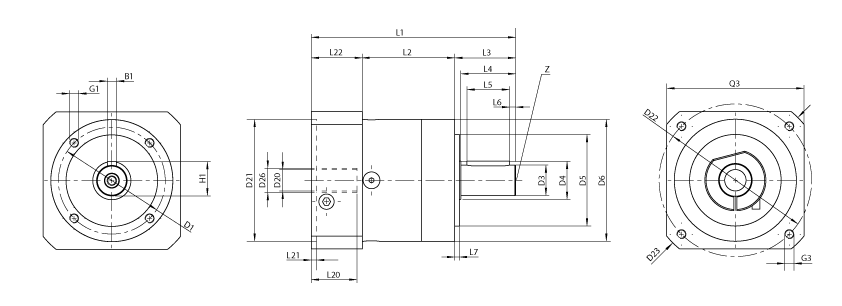

Dimensions.

| Geometry | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | Rapp. | STADI | ||

| Pitcvh circle diameter output |

D1 | 34 | 52 | 70 | 100 | 145 | |||

| Shaft diameter output | D3 | h7 | 10 | 14 | 20 | 25 | 40 | ||

| Shaft collar output | D4 | 12 | 17 | 25 | 35 | 55 | |||

| Centering diameter output | D5 | h7 | 26 | 40 | 60 | 80 | 130 | ||

| Housing diameter | D6 | 40 | 60 | 80 | 115 | 160 | |||

| Mouting thread x depth | G1 | 4x | M4x6 | M5x8 | M6x10 | M10x16 | M12x20 | ||

| L1 | 88.5 | 106 | 133.5 | 176.5 | 255.5 | 1 | |||

| Min. total length | L1 | 101.5 | 118.5 | 150.5 | 204 | 305 | 2 | ||

| L1 | 114 | 131 | 168 | 235.5 | - | 3 | |||

| L2 | 39 | 48 | 60 | 74 | 104 | 1 | |||

| Housing length | L2 | 52 | 59.5 | 77.5 | 105.5 | 153.5 | 2 | ||

| L2 | 64.5 | 72 | 95 | 129 | - | 3 | |||

| Shaft length output | L3 | 26 | 35 | 40 | 55 | 87 | |||

| Centering depth output | L7 | 2 | 3 | 3 | 4 | 5 | |||

| Output shaft withy feather key (DIN6885-1) | A 3x3x18 | A 5x5x25 | A 6x6x28 | A 8x7x40 | A 12x8x65 | ||||

| Feather key width | B1 | 3 | 5 | 6 | 8 | 12 | |||

| Shaft height including feather key | H1 | 11.2 | 16 | 22.5 | 28 | 43 | |||

| Shaft length from shoulder | L4 | 23 | 30 | 356 | 50 | 80 | |||

| Feather key length | L5 | 18 | 25 | 28 | 40 | 65 | |||

| Distance from shaft end | L6 | 2.5 | 2.5 | 4 | 5 | 8 | |||

| Center hole | Z | M3x9 | M5x12.5 | M6x16 | M10x22 | M16x36 | |||